Challenges along the supply chain

In short:

- The global leather supply chains are facing a number of sustainability challenges due to leather chemistry including impacts on environment and health, compliance issues, lack of traceability and business models.

- The project team conducted a scenario process that yielded a number of factors that influence the use of chemicals along the supply chains – today and in 2035.

The manufacturing process of leather requires the use of chemicals. Legal requirements and specifications developed by the chemical industry on the careful use of chemicals aim to prevent harm caused by chemicals to humans and the environment. In the modern leather industry, however, global supply chains are the norm, which confronts brands and retailers with enormous challenges: in the control of processes (leather production and processing, other business processes), in compliance activities, and in the ability to actively push the implementation and development of a "more sustainable chemistry" from their suppliers.

Chemicals in tanning: Direct and indirect exposure to humans and the environment

The chemicals used throughout each production step can cause harm to humans and the environment in many ways. This applies to the entire life cycle of a leather product - starting at the slaughterhouse, where the skin is obtained as a raw material as a by-product, through the various tanning stages up to the shoe factory for instance. Many of the chemicals are problematic, e.g. labelled as hazardous based on the Globally Harmonized System of Classification and Labelling of Chemicals (GHS) .

For further production steps after the slaughtering process, the rawhide is preserved. Problematic substances (biocides, fungicides etc.) may be used used. However, as these substances are expensive to purchase the "household chemical" salt is often used, which also poses a risk to ecosystems if wastewater is not properly disposed of. Refrigeration is often not available as a preservation method because of the technical and logistical effort and the (energy) costs involved. Preservation may also be necessary in the further life cycle during the (intermediate) storage of the processed rawhide and the end product.

In the so-called beamhouse, the hides have to be dehaired and degreased by chemical processes for the subsequent tanning process, which is usually - and to some extent necessarily - done by using "aggressive" chemicals.

With regard to the actual tanning process, three basic types - mineral, vegetable and synthetic tanning - can be distinguished, although in practice mixed forms of these methods often occur. More than 80 per cent of the leather available worldwide was processed using tanning agents, which are based entirely or partially on the mineral chemical chromium. Chromium is considered to be a comparatively efficient tanning chemical and poses, in this formulation, no significant risks to humans or the environment. However, chrome III can oxidise to the problematic substance chromium VI, which is classified as a carcinogen and may have a sensitising (allergenic) effect. Chromium VI is mainly caused by procedural errors during the tanning process, but can also be formed in the further life cycle of the leather as a result of (improper) handling. The alternative tanning chemicals can also be a hazard for humans and the environment. Thus, aldehydes which are used for synthetic tanning are also equipped with hazard labels. In addition, the production of these substances, like almost all commercially available organic chemicals, are usually based on fossil raw materials. Vegetable tanning agents have a favourable toxicological profile with regard to their intrinsic properties. However, vegetable tanning also results in a pollution of waste water, as it has a higher chemical and biological oxygen demand than e.g. chromium. Furthermore, the ecological and health-related consequences in regard to the cultivation of vegetable tanning agents must be considered (land use, monocultures lead to loss of biodiversity, competition with food supply). Consequently, all common tanning methods have specific advantages and disadvantages.

The tanning process is followed by the "finishing" of the leather, a process in which chemicals optimize the surface of the material with respect to the desired properties (protection against moisture, UV resistance, dyeing, etc.). For this purpose, the leather is for example lacquered or laminated.

Afterwards, downstream actors may process the leather into end products. Here, too, the material is often exposed to chemicals, such as adhesives (e.g. in shoes), which can cause adverse (side) reactions of the chemicals in the leather.

Legal requirements in the EU and in some cases at other locations regulate many of the problematic substances used in leather production and restrict or otherwise regulate their use (e.g. through reporting obligations). This applies, for example, to some of the per- and polyfluorinated chemicals (PFCs) used in the finish. A key issue is the restriction under the EU chemicals regulation REACH of chromium VI in leather products that may get into contact with the skin. Internal controls by - sometimes well-known - brands or by enforcement authorities show that the chromium VI limit of 3 mg/kg (0.0003 weight percent) is frequently exceeded in leather products. Many companies make considerable efforts to reduce their compliance risks, e.g. by selecting reliable suppliers and by chemical testing of products before they are placed on the market. Current control procedures can reduce the risk of product contamination with chromium VI and other regulated substances - but they cannot provide any guarantee.

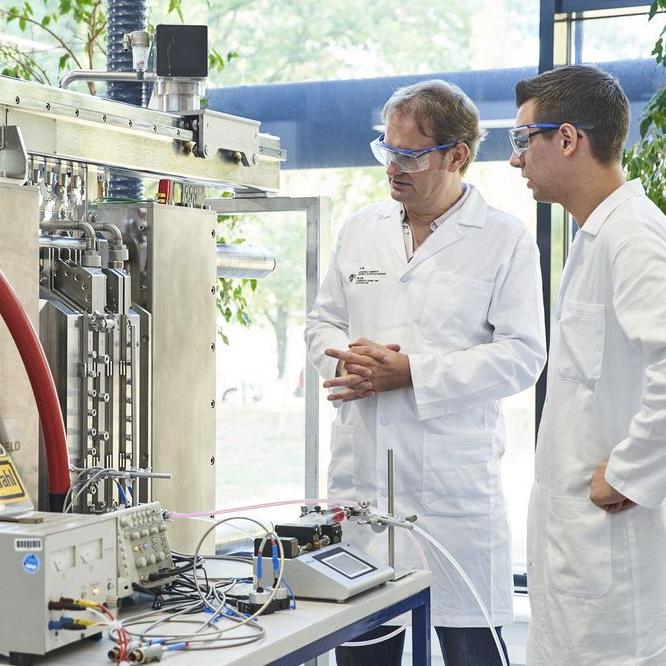

Professionalized workflows and the use of state of the art process technologies can avoid many of the hazards described. While the leather industry based in Germany obtains the relevant know-how, the capacities for waste water treatment at some locations within the EU are already reaching their limit. In addition, the situation concerning leather production in developing countries is much more problematic. Here, unskilled personnel often manages the control of the complex chemical processes of tanning; there is also a lack of investment in modern environmental technologies and of experts to operate them.

Large parts of the leather industry have moved to locations in the "global south", where leather can be mass-produced in the low-wage sector. The priority here is production at low labour and investment costs. Although Europe's tanneries are investing in environmental technologies, they have reduced the amount of research and development activities considerably due to cost pressure. They mainly focus on optimising existing processes (incremental innovations). The chemical industry in Europe plays a leading role in the global market for leather chemicals. It provides the auxiliaries for the common manufacturing processes of leather and thus profits from the dominance of chromium tanning.

In today’s leather industry, global supply chains are the norm, which confronts brands and retailers with enormous challenges concerning controlling processes. A typical supply chain could look like this: Breeding and slaughter in South America, tanning to wetblue (tanned leather immediately after chrome tanning) in India, dyeing and finishing in China, manufacturing the product (e.g. shoe) in Vietnam, distribution in North America or Europe. The brand located in Europe has contact with its direct supplier, i.e. usually the importer. However, the identity of sub-suppliers regularly remains hidden to the brand. Traceability of which chemicals were used in which process and by whom (with further information on production methods, occupational health and safety, waste management, social aspects, etc.) exists – at best – only in the automotive industry. This makes the process control, compliance measures and the ability of brands to actively request "more sustainable chemistry" from their suppliers more complicated.

In the light of sustainable development in relation to leather chemistry, global supply chains are based on established business models, which can impede creative thinking towards a more "sustainable" leather chemistry. New or further developed approaches are needed. Starting points for this include process and product innovations, more effective and efficient supply chain management as well as business practices such as "product-service-systems".

Problem description based on influencing factors for the use of chemicals in the leather industry

In 2019, a scenario process with actors from the leather supply chain (chemical industry, tanneries, consumer trade, automotive) and other stakeholders (NGOs, science) took place in the leather project of the Darmstadt University of Applied Sciences. One result of this process was the initial identification of factors influencing the use and handling of chemicals in the global leather value chains. For each influencing factor, there is also a brief outline of the status quo:

|

Definition |

Status Quo |

|---|---|

|

Derive from the fields of application of leather and the use behaviour of leather products. |

Leather is very widespread and is used in a variety of products. So far, there are enormous differences in quality. For some applications there is no comparable substitute material available yet. However, developments (e.g. in the field of plastics) indicate that this could be expected to become the case. The demands on the functionality of leather depend strongly on the application and on the region. |

|

Definition |

Status Quo |

|---|---|

|

Includes occupational safety, health protection and wages in the production countries. The working conditions are primarily related to the leather industry (and its customers) (see also "Location factors"). |

Working conditions in the producing countries (e.g. the global South) are poor to catastrophic. Especially if only the domestic market is supplied. If there are international purchasing relationships with the production companies, working conditions improve. |

|

Definition |

Status Quo |

|---|---|

|

CO₂ emissions generated in the leather value chains - including meat production. Adaptation measures are implied. |

The production of leather (including transport, input materials such as chemicals, tanning process) as well as meat and milk are highly relevant to greenhouse gases. However, in certain sectors (high quality requirements) there is already a trend towards re-regionalisation, which has a positive effect on CO₂ emissions. |

|

Definition |

Status Quo |

|---|---|

|

Laws and e.g. international regulations (including ILO standards) regulate the use of chemicals in leather production (including (eco)toxicological requirements), whereby national differences exist and global standards are lacking. |

Currently there are completely different situations in the purchasing countries with more stringent regulatory standards (protection of the environment, consumers, workers, animal welfare) and the supplier countries, where such standards either do not exist or are not applied/enforced. |

|

Definition |

Status Quo |

|---|---|

|

Includes NGOs, press, media, specific consumer groups and other stakeholders. Accidents and scandals, e.g. in production countries, and protests influence the (critical) public. It also creates awareness of (eco)toxicological aspects. |

The critical public has knowledge about chemicals in leather and the manufacturing processes, and is influential. It has taken up the issue of chemicals in leather and has the platforms to disseminate information. |

|

Definition |

Status Quo |

|---|---|

|

Includes horizontal and vertical cooperation, i.e. new forms of industry cooperation (horizontal) and integration in the supply chain (vertical). Transparency, willingness to dialogue and the culture of cooperation have an effect on organisational innovation. |

Currently, with regard to organisational innovation a heterogeneous situation is notable. There are selective horizontal cooperations (e.g. Leather Working Group). Vertically, there are especially mergers (integration) of direct suppliers ("Tier 1") and first sub-suppliers. |

|

Definition |

Status Quo |

|---|---|

|

Result primarily from research and development, which concern both leather and artificial leather. Durability and recyclability are relevant directions for innovation. |

New leathers are constantly developed in various forms and specifications. However, many of these developments are not successful on the market. They usually come from a niche and serve a small market. |

|

Definition |

Status Quo |

|---|---|

|

Determined by costs for raw hides, chemicals, energy, water and disposal as well as labour costs, among other things. |

High production costs in locations with stringent standards such as the EU (protection of the environment, consumers, workers, animal welfare) are usually offset by low production costs in locations with low standards (mostly global south). |

|

Definition |

Status Quo |

|---|---|

|

Innovations in tanning or in the chemicals and processes used. |

Processes and process innovations vary from region to region. In principle, little use in made of automation. Processes are hardly individualised. Process innovation is almost exclusively driven by the few „global players“ Overall, the leather industry is a sector steeped in tradition that tends to be sceptical about process innovations. |

|

Definition |

Status Quo |

|---|---|

|

The quality of the leather depends on the quality of the raw hides. Care, age and thus indirectly the origin of the animals affect the quality of the rawhide. |

Depending on the location, for example, there are large differences in the quality of the hides, whereby particularly good quality is associated with a corresponding effort in rearing. Supply chains with "cheap products" from India and Bangladesh, for example, are facing increased pressure. |

|

Definition |

Status Quo |

|---|---|

|

Related to the ability to identify the chemicals used in the supply chain and the associated processes and responsible actors. In this context, traceability is a decisive advantage to be compliant with dynamic legal requirements and other specifications (e.g. from substance lists such as the MRSL on process chemicals of the Brands Initiative Zero Discharge of Hazardous Chemicals/ZDHC as well as from certificates and product labels). |

The traceability of substances in (leather) products and processes is rather low. It can only be achieved at great effort and expense, partly due to complex supply chains. There are regional differences, as in Europe, North America and China, for example, legal requirements are in force and enforced that (implicitly) require traceability at least to some extent. Working methods and a lack of infrastructure in the supplier countries (mostly in the global South) make traceability even more difficult. Moreover, a culture of "openness" prevails, especially in Europe - as a basic prerequisite for transparency and thus also for traceability. In a few sectors (including automotive) traceability is already partially possible. |

|

Definition |

Status Quo |

|---|---|

|

Political, social and cultural conditions and developments (which are beyond the direct influence of the leather industry) (see also "Working conditions"). |

Locations with less restrictive standards (protection of the environment, consumers, employees, animal welfare) are attractive for brands due to lower production costs. The policy of these locations manifests these "competitive advantages", for example through a lack of law enforcement. The low-wage sector is dominant, which means prosperity for only a few. At the same time, low income deprives the population of opportunities for education, a key prerequisite for critical consumption, but also for the enforcement of workers' rights, for example. |

|

Definition |

Status Quo |

|---|---|

|

Presence of transparency and knowledge in the various steps of the supply chain with regard to the use and effects of chemicals in the process and the end product. |

Transparency and knowledge decrease along the supply chains: The chemical industry has comprehensive information on its (chemical) product properties (less so on the specific conditions of use in the tanneries); tanneries have detailed information on the aspects relevant to them (including environmental effects); brands have only selective information. The level of information available to consumers is even lower. |

|

Definition |

Status Quo |

|---|---|

|

Purchases and product uses are determined by the requirements and expectations of the product as well as lifestyle (attitude) and fashion trends. |

Factors such as design, fashion trends, marketing measurements, price and material properties (UV-resistant, waterproof) determine consumer behaviour. A small number of consumers take the use and handling of chemicals in production into account when deciding to buy leather. |

|

Definition |

Status Quo |

|---|---|

|

Natural raw materials (e.g. as a basis for tanning agents) as well as components of the environment such as soil, air, water. |

In the production countries are high levels of emissions of chemicals in various environmental media (air, water, soil), with impacts on ecosystems. Scarcities exist in connection with climatic changes (crop failure). With regard to land use, different interests and objectives must be balanced. Alliances exist for the protection of natural resources. |

|

Definition |

Status Quo |

|---|---|

|

This includes all production resources not directly taken from nature, especially raw hides, energy, chemicals, but also technical production resources (production plants). |

The rawhide markets are highly volatile; at present there tends to be an oversupply of low quality hides (origin: mostly global south). A rich portfolio of leather chemicals is available, but in some cases there is a lack of alternatives (e.g. to mineral tanning while maintaining leather properties). Production plants of various types (size, semi-autonomous, etc.) are also available, but infrastructure in consumer countries (e.g. waste water treatment) is better developed. High-quality means of production are also associated with higher costs, which in some cases exceed the financial possibilities in third countries. |